safe in motion

with the digital handshake

Industry 4.0

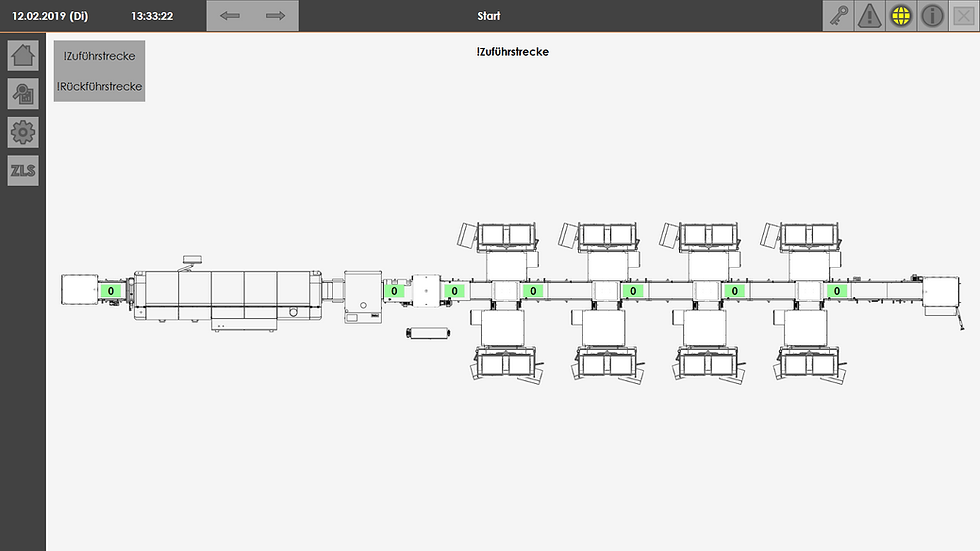

Centralised control system (ZLS) from haprotec - Intelligent control and data management for production lines

haprotec's centralised control system (CCS) is a proprietary software solution for smart route control and data management in automated production lines. It enables intelligent process control, traceability and seamless integration into existing MES systems (Manufacturing Execution Systems). The ZLS efficiently centralises the entire system control, monitoring and management.

The system consists of two main components:

1. ZLS server service - Responsible for route management, data management and user management.

2. the ZLS control centre - the intuitive user interface for monitoring and controlling the production line

The hardware for the ZLS can either be provided by haprotec or integrated into the existing IT infrastructure according to a customised specification. Installation on virtualised systems is also possible by arrangement.

Main functions of the haprotec ZLS

The haprotec ZLS offers a wide range of functions to enable efficient control and monitoring of production processes.

User and role administration

The ZLS contains an integrated user and role management system that regulates access to various functions. This allows individual authorisations to be assigned and work processes to be controlled securely.

Versioned recipe management

The ZLS offers versioned recipe management for standardised process control. This means that different production recipes can be saved and managed and older versions can be accessed at any time.

Intelligent routing and programme allocation

The ZLS enables flexible routing for workpiece carriers within the production system. The intelligent navigation ensures

- Automatic return to a defined station or the point of origin

- Optimised management of inserted workpiece carriers

- Customisable programme assignment for different production processes

Real-time monitoring and data analysis

The user interface provides companies with a project-specific system overview that visualises

- Visualises overall and partial system statuses

- Displays the system status and machine utilisation

- Enables workpiece tracking in real time

The ZLS also records and analyses process data for each workpiece carrier to ensure efficient production control.

Message system with plain text history

The reporting system offers a detailed error analysis with plain text messages and historical error logging. This helps to identify problems more quickly and minimise downtimes.

Customisable translation of the user interface

Thanks to modular language management, the ZLS interface can be customised to different languages.

Powerful API for integration into MES and PLCs

The ZLS supports:

- GraphQL API for communication with higher-level MES systems

- OPC UA interfaces for direct connection to PLC controllers

This ensures manufacturer-independent, secure and efficient data integration into existing production environments.

Data backup and IT integration

The responsibility for data backup lies with the customer, whereby haprotec is happy to provide advice and support. The ZLS can be operated both on dedicated hardware and on virtualised servers.

The haprotec ZLS provides companies with a powerful, scalable and intuitive solution for automating and monitoring their production processes. Intelligent routing, seamless traceability and comprehensive data integration maximise production efficiency.